How to extend the service life of impact crusher?

- 2024-04-25

- view count:

Impact crusher is one of the commonly used machines in the mud, sand and gravel industry. Mainly used for crushing limestone, sand granite and other stones. Crusher accessories are an important part of the impact crusher and need to be replaced regularly. They are called impact crusher wearing parts in the industry.

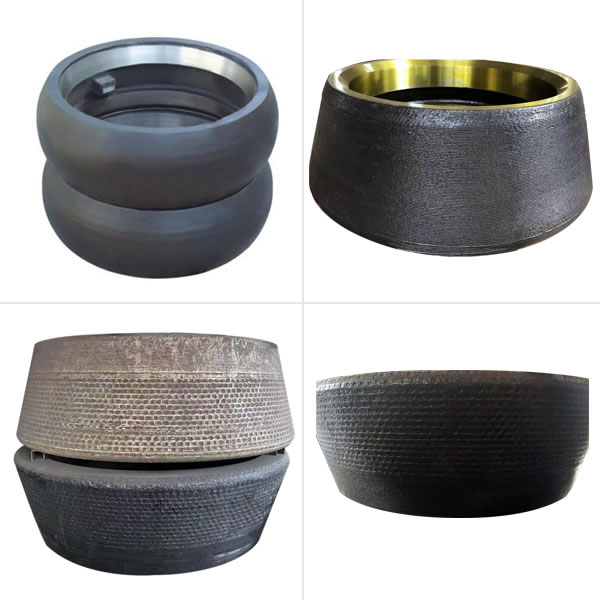

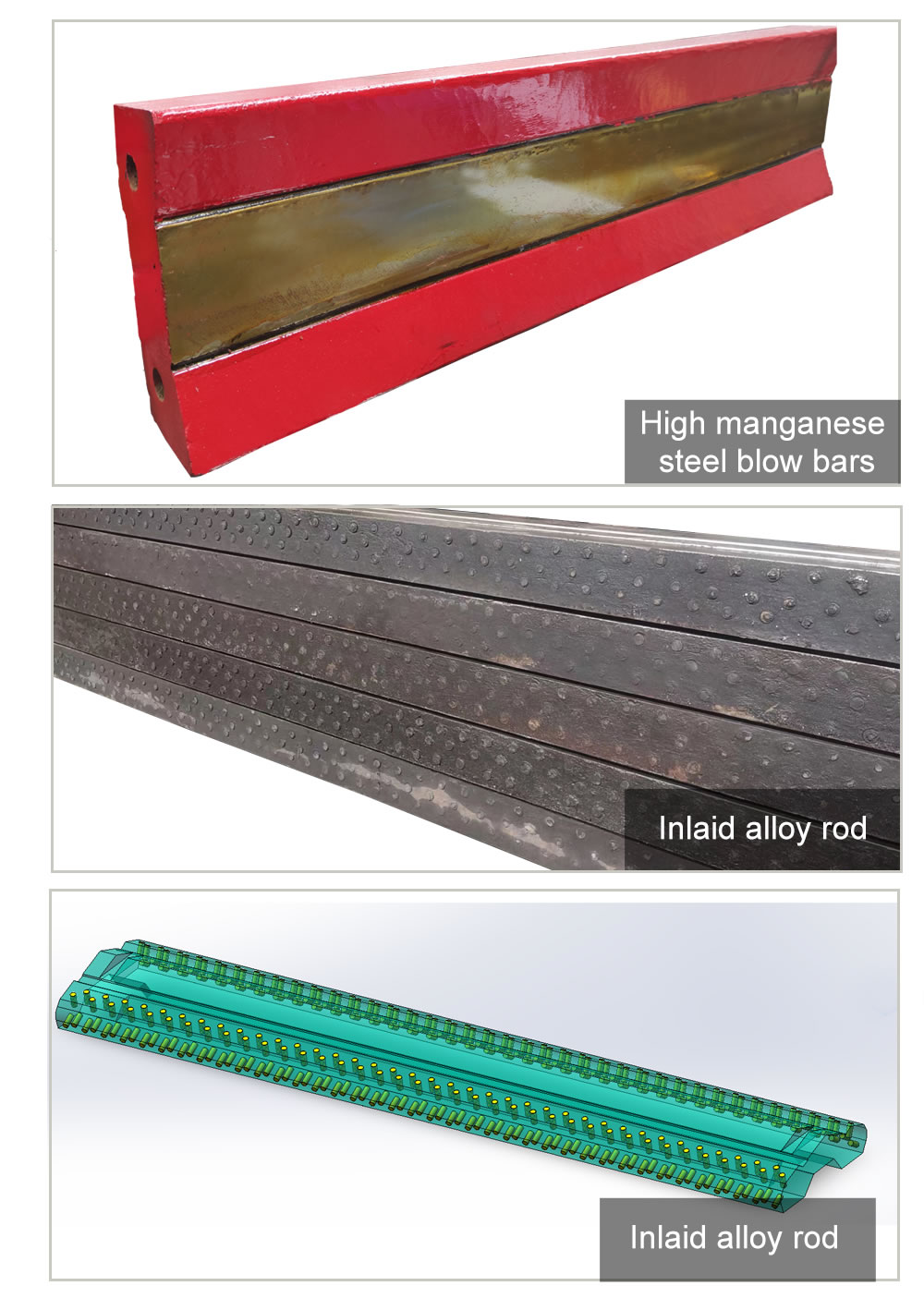

Zhili New Materials Company specializes in manufacturing wear-resistant parts for crushers. Our company has been established for more than 30 years and has rich industry experience and a professional team that can provide you with solutions. The wear-resistant parts we produce mainly include hammer heads, blow bars, liners, etc. The accessories are cast from high-manganese steel, high-chromium, high-manganese composite and other wear-resistant materials. The blow bars is made of high chromium alloy material and the latest manufacturing technology, with unique structural design and finished product. The product has no tension and cracks, and the grain shape is quite good. It is a trustworthy and highly wear-resistant casting. When the blow hammer is worn to a certain extent, it must be replaced in time to avoid damage to fasteners and other components. Our impact crusher plate hammers are made of modified high manganese steel, ultra-high manganese, ultra-high chromium cast iron, and are treated with composite materials. The solidification method is controlled during casting and the heat treatment process is optimized. The casting has high hardness, good toughness, high impact resistance and strong wear resistance, and is suitable for the working needs of various types of crushers.

Our casting designers will draw you and recommend suitable materials based on the working conditions. We design lightweight and highly wear-resistant accessories with users in mind. Help enterprises save costs and do everything possible to extend the service life of machines.