Crusher Jaw Plates

Global Sales OEM tailor design

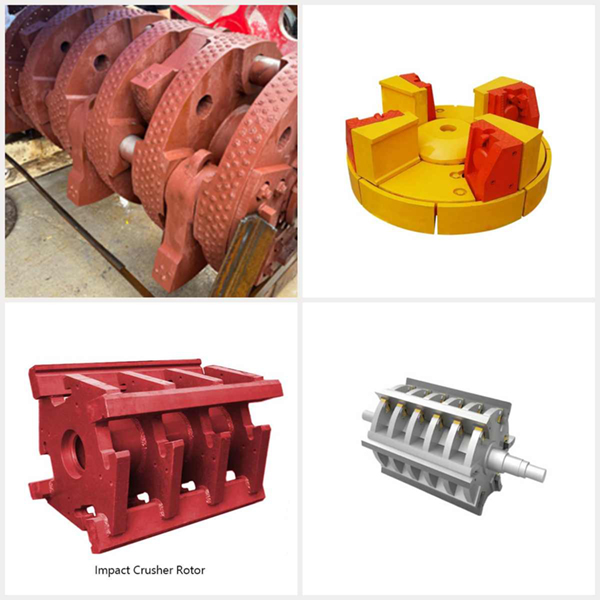

Product name: Jaw plate/Swing Jaw Plate/Fixed Jaw Plate/Movable Jaw Plate/Jaw Crusher Liners/Jaw Dies

Production process: Casting

Applicable machines: Jaw crushers

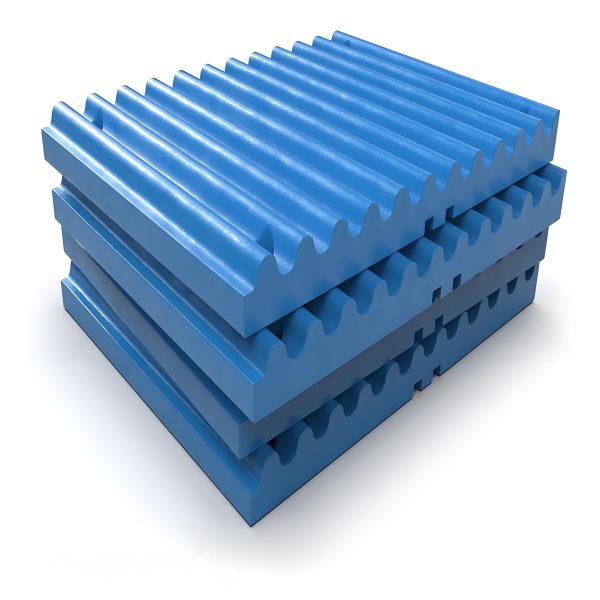

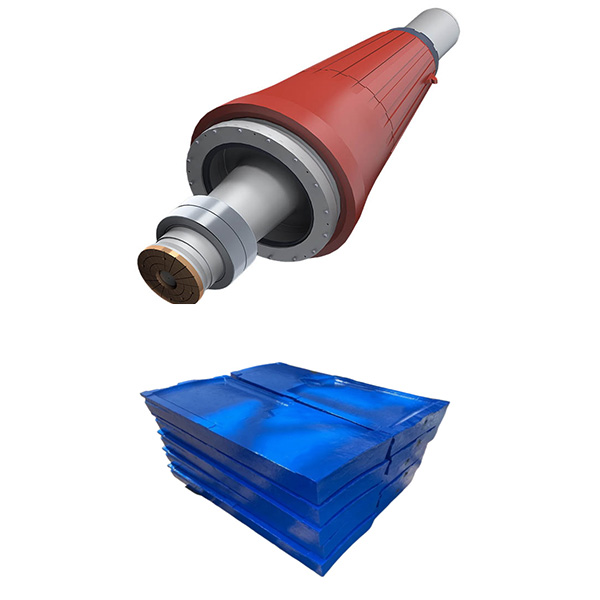

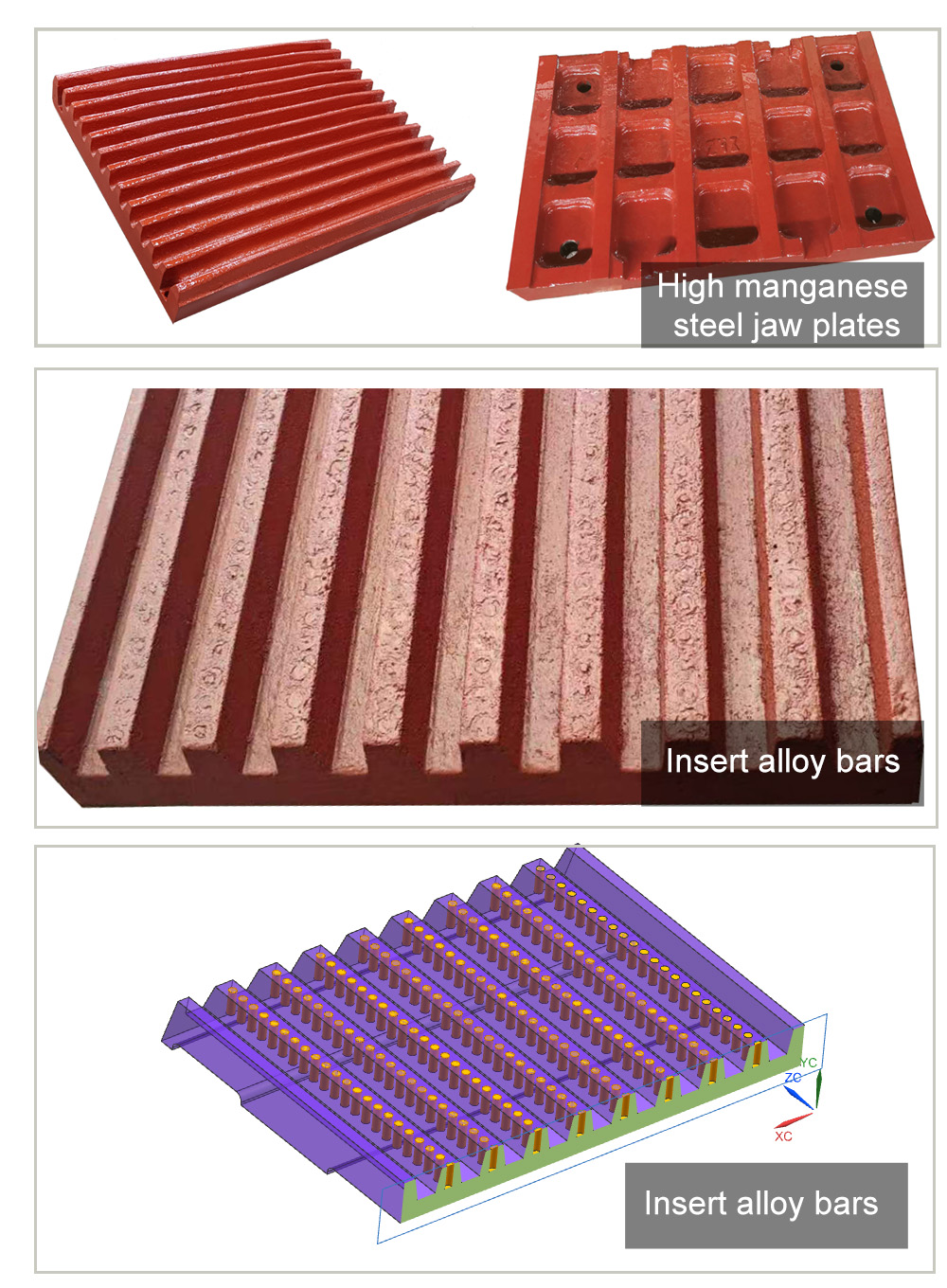

Material types: High manganese steel(Mn13Cr2/Mn18Cr2), high manganese steel insert titanium alloy bars, high manganese insert titanium alloy bars and hardfacing, high chromium cast iron, alloy steel, etc.

Applicable industries: mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(zhiliwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.

The wear-resistant solution for jaw crushers depends on whether you are engaged in quarrying, mining or recycling, choose the most suitable jaw plate.

Our Jaw plates are cast from the highest grade of ferro Manganese, to provide the hardest composition for maximum wear resistance. We offer a wide variety of tooth profiles & surface shapes to best suit your crushing needs.

The materials of high manganese steel Jaw plates include Mn13Cr2, Mn18Cr2, Mn13 or Mn18 insert titanium alloy bars and hardfacing.

Applicable working conditions: Suitable for cement plant, stone factories and other rocky places with poor conditions.

Zhili New materials jaw plates have the following features:

1. Designed for maximum operational flexibility;

2. Maximize uptime;

3. Reduce wear;

4. Optimize production;

5. Extend service life.

Chemical component

Grade | Chemical component% | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| 1:Allowed to add microscale V,Ti,B and Re etc. 2:We can produce the other grade high manganese steel hammer according to customers’ requirments. | ||||||

Mechanical Property

Grade | Stretch property | Hardness HB | |||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Elongation at cross section % | Shock absorption energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

We use proper alloying and and related technological measures to make High chromium iron Jaw plates’surface hardness reaches more than 58HRC , during the process of wearing will maintain high hardness and high wear resistance.

Applicable working conditions: Suitable for making wearable spare parts with lower impact load and simpler shape.

Chemical component

Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

| 1:Allowed to add microscale V,Ti,Nb,B and Re etc. 2:We will choose grade and specific component according to blow bars’ weight ,thickness and sizes. | |||||||||

Mechanical Property

Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

Casting condition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1:There are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used. | ||||||

Alloy steel jaw plate is a widely used at present. It has relatively high hardness and appropriate toughness which is enough to resist the fluid wear and repeated impact of the material, so it shows good wear resistance performance.

Applicable working conditions: Widely used in Cement, Quarry and Mining plants