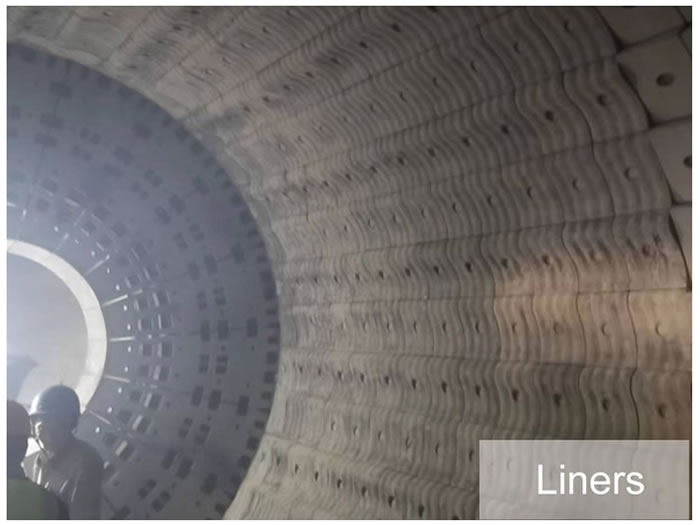

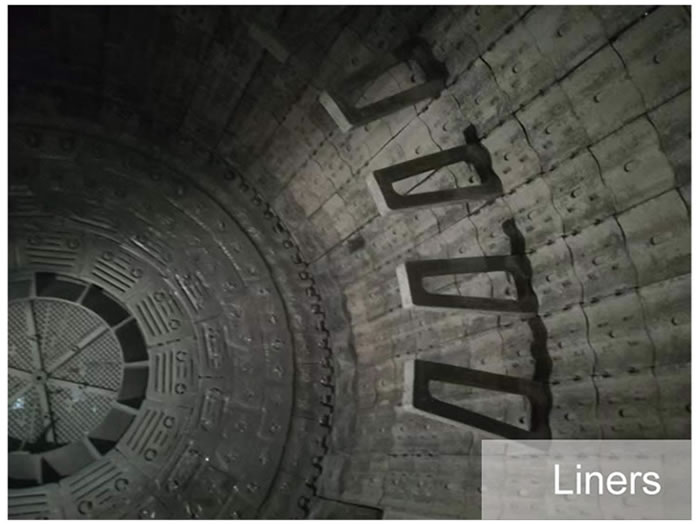

Crusher Liners

OEM tailor design

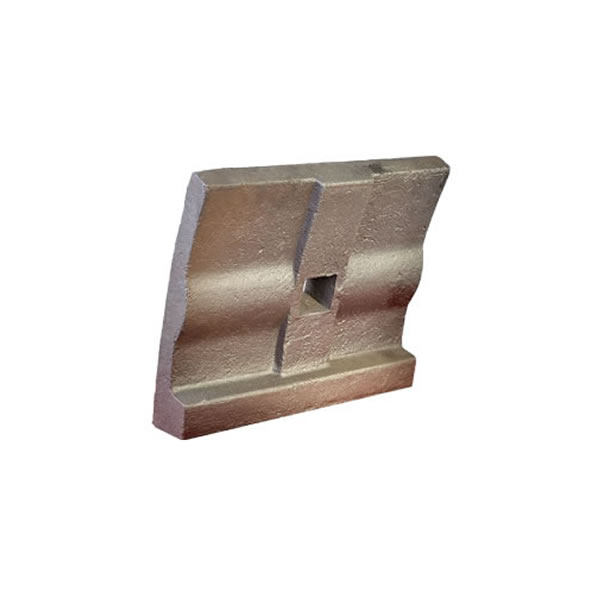

Product name: Crusher Liners/Mill liners/Vertical mill liner

Production process: Casting

Applicable machines: crusher,vertical mill,ball mill,mill

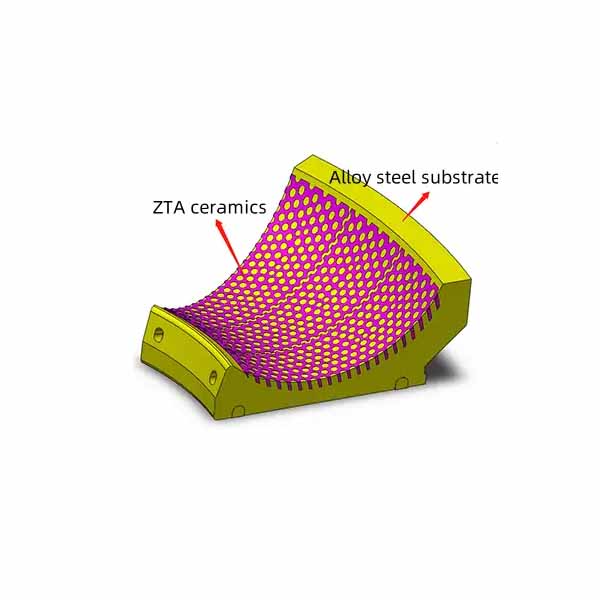

Material types: High manganese steel(Mn13Cr2/Mn18Cr2), bimetal composite, high chromium cast iron,Ceramic-metal composite,alloy steel, nickel hard cast iron,etc.

Applicable industries:mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(zhiliwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.

Our premium manganese steel and alloy crusher liners in mining and aggregate production to achieve and often exceed the performance of the equivalent Original Equipment Manufacturers castings.

Available in our M14, M18, and M21 material grades we have a cost-effective solution to your specific requirements.

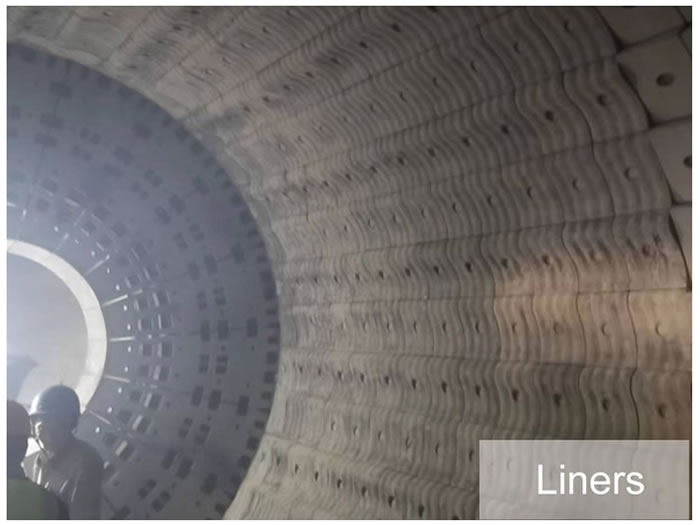

We can provide high-quality liners for various crushers, vertical mills, ball mills, and semi-autogenous mills. The materials can be customized according to your working conditions to extend the service life and improve efficiency.

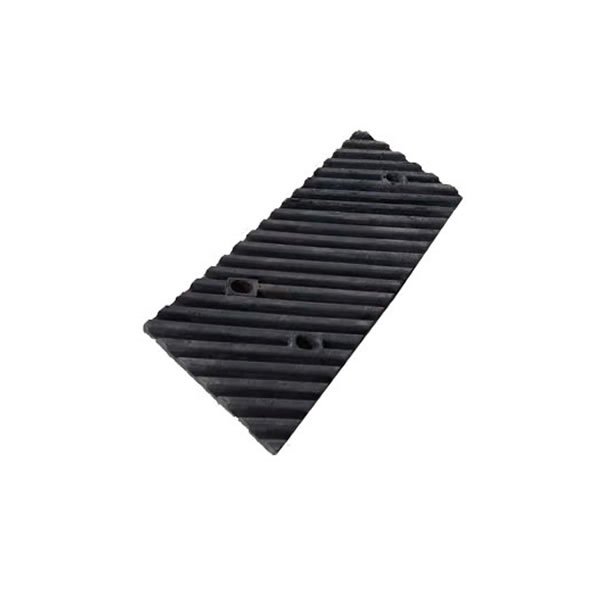

Product material: high chromium cast iron

Chemical formula of raw materials: BTMCr15

Hardness: HRc50 ~ 58

Applications: Clinker silo guards in cement plants, port machinery chute linings, steel mill hopper linings, port machinery silo high wear-resistant plates, coal bunker wear-resistant protective plates.

| High Chromium Cast Iron Cement Mill Liner | |

|---|---|

| Mill liner thickness: | 18mm, 15mm, 20mm, 15mm, 30mm, 32mm, 40mm, 50mm, 60mm, 80mm, 100mm; |

| Section thickness: | 1", 2", 3", 4", 5", 8", 10", 20", 30", 40". |

Product material: chrome molybdenum alloy steel

Applications: cement mill, coal mill in power plants, ball mill in mines, autogenous mills and semi-autogenous mill.

Chrome Molybdenum Alloy Steel Mill Lining | |||||||

|---|---|---|---|---|---|---|---|

| Chemical component % | C | Si | Mn | Cr | Mo | P | S |

| AS 2017/L2A | 0.45-0.55 | ≤0.75 | 0.50-1.00 | 0.80-1.20 | – | ≤0.04 | ≤0.04 |

| AS 2017/L2B | 0.55-0.65 | ≤0.75 | 0.50-1.00 | 0.80-1.50 | 0.2-0.4 | ≤0.04 | ≤0.04 |

| AS 2017/L2C | 0.70-0.90 | ≤0.75 | 0.50-1.20 | 1.30-2.40 | 0.2-0.4 | ≤0.04 | ≤0.04 |