Jaw Crusher Cheek plate/Toggle plate

Global Sales OEM tailor design

Product name: Jaw Crusher Cheek plate/Toggle plate

Production process: Casting

Applicable machines: Jaw crushers

Material types: medium manganese steel (Mn8), high manganese steel (Mn13-2, Mn13-3, Mn13Cr2),nodular cast iron, etc.

Applicable industries: mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(zhiliwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.

Jaw Crusher Cheek plate

A wide range of premium quality jaw crusher cast cheek plates are available for all brands of jaw crushers. Our jaw crusher cheek plates are cast from the highest grade wear resistant grades with the hardest composition for maximum wear resistance. We offer a wide range of grades and surface shapes to best suit your crushing needs.

Features & Benefits:

① Product can be infused with tungsten carbide for extended life;

② Installed with a wear surface hardness of 90 Rockwell A;

③ Reduced crusher downtime and fewer cheek plate changes;

④ Available for most popular jaw crusher models;

⑤ Custom designs to meet specific customer needs or wear conditions.

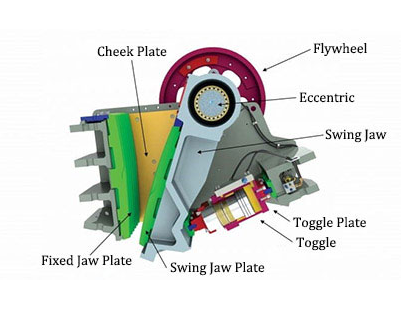

Jaw crusher structure diagram

Toggle Plate is a simple & low-cost but very important part of jaw crusher.

It is usually made of wear-resistant material, and it is used to hold the lower part of the jaw in position, it also serves as a safety mechanism for the entire jaw.

If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through the jaw, the toggle plate will crush and prevent the whole machine from further damage.

The toggle plates in jaw crushers produced are made by adding rare and precious metals such as chromium, vanadium, boron, molybdenum, etc., and we use special transformation techniques on the basis of original Mn13 material. This type of product has excellent wear resistance. Based on the mechanical performance of the jaw crusher model on the customer’s site, the appropriate heat treatment method of high manganese steel is determined to ensure that this type of product reaches its maximum crushing force and the toggle plate reaches its brittle fracture point.

Why Choose Zhili New Materials Toggle Plates?

① We offer equivalent OEM replaceable toggle plates;

② We produce high-strength toggle plate to better transmit the crushing force to the back of body frame;

③ We extend the service life of the toggle plates;

④ We provide more competitive prices;

⑤ We provide more professional services and suggestions.