Roller press side baffle/Cheek plate

Global Sales OEM tailor design

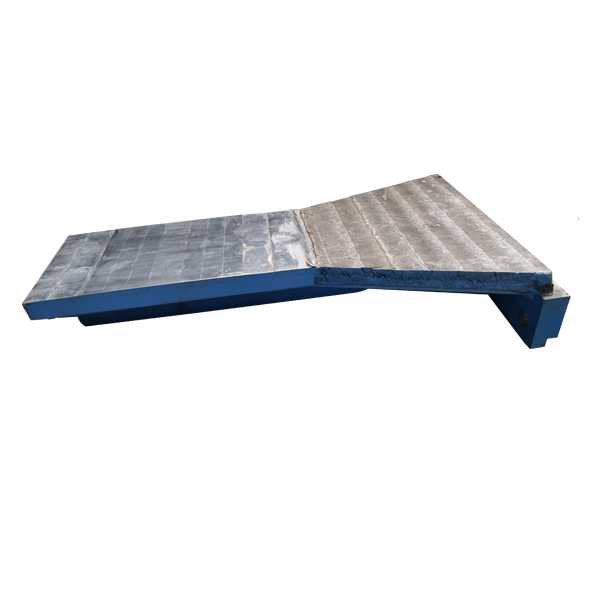

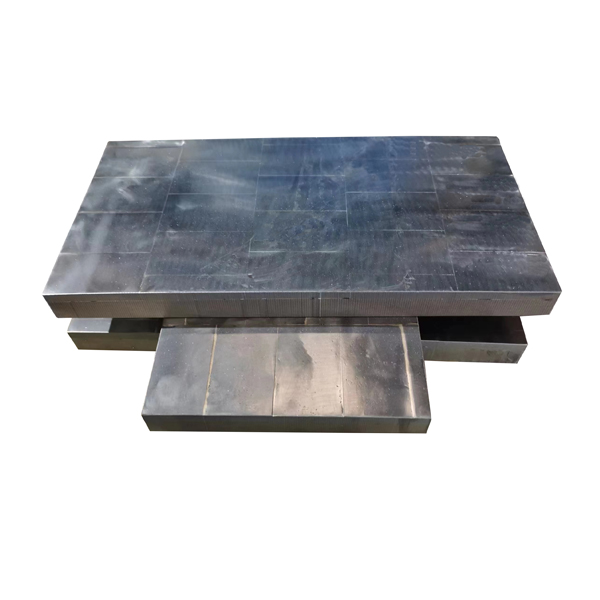

Product name: Roller press side baffle/Tungsten carbide side baffle

Production process: casting

Material types: Tungsten carbide,Wear-resistant cast iron,composite steel plate,etc.

Applicable industries: Cement, metallurgy, chemical industry, steel, pellets, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4.Ensure that the quality of the purchased components is impeccable,and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(zhiliwearparts@lyzhili.com), because we are a custom factory for wear-resistant castings.

The roller press side baffle is an important device to limit the material on both sides of the roller. It plays a vital role in reducing material leakage on both sides, reducing the edge effect of the roller press, and improving the effective work of the roller press. The tungsten carbide plate and the steel plate are effectively compounded to produce a tungsten carbide composite plate. While having the super wear resistance of tungsten carbide, it solves the problem that tungsten carbide materials cannot be welded and installed with the mounting base.

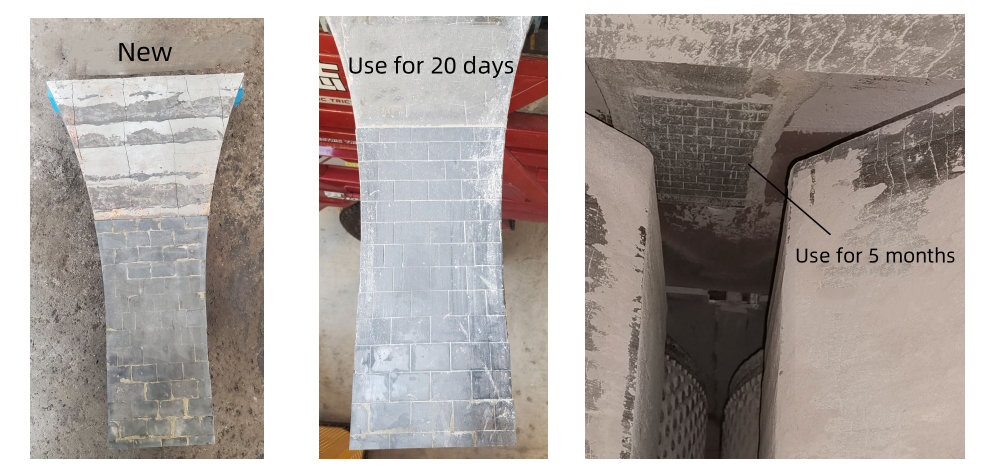

When the gap between the side baffle and the roller end face is small, the side baffle is subjected to the outward extrusion force of the material between the rollers while bearing the material scouring. Under such high stress wear conditions, the side baffle is very easy to wear, especially in the area with the smallest gap between the two rollers, where the wear is faster.

Through wear test data and actual on-site use verification, our company's tungsten carbide side baffle is used on the high-pressure roller mill in the mine, and the service life can reach more than 6 months. Used on cement and raw material roller presses, the service life can reach more than 10~12 months.

Wear diagram of tungsten carbide side baffle