Vertical mill roller/Grinding roller

Global Sales OEM tailor design

Product name: Vertical mill roller,Roller sleeve,Grinding roller,Conical Roller,Wheel Roller,Extrusion roller of roller press

Production process: Casting

Applicable machines: Vertical mill

Material types: high chromium cast iron, Ceramic-metal composite,Hardfacing,Medium alloy steel etc.

Applicable industries: Mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(zhiliwearparts@lyzhili.com), because we are a customized factory for wear parts.

At present, the grinding roller forms used in vertical roller mills in various industries can be divided into two types according to the shape, namely, conical roller and wheel roller.

As a professional cement equipment parts manufacturer, Zhili New Materials can manufacture matching mill rollers for customers according to their drawings or VRM models. We have continuously developed and improved the production process and manufacturing technology over the decades of the production process. At present, we have mature VRM grinding roller production technology. We are committed to improving the wear resistance of the roller of the vertical mill, optimizing the grinding process, and helping customers save maintenance costs.

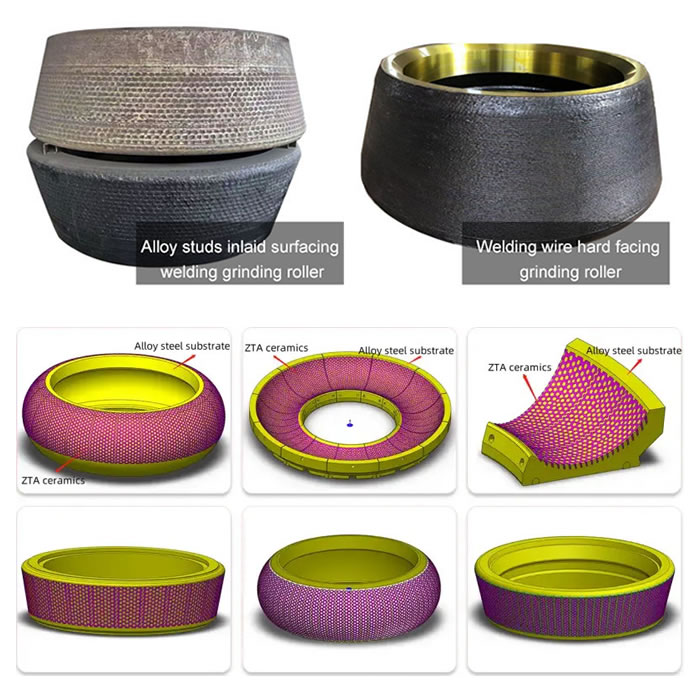

The materials of the grinding roller we produce are mainly high chromium cast iron, high chromium + surfacing, Medium alloy steel(alloy studs) + surfacing, ceramic alloy composite, etc.

High chromium + surfacing

The most material of grinding roller is high Chrome,add the surfacing welding can extend lifetime and reduce costs and improve efficiency.Surfacing welding include Welding wire hard facing and Alloy studs inlaid surfacing welding.

Welding wire surfacing grinding roller improves the wear resistance and service life by surfacing wear-resistant welding wire on the surface of the roller body.

Medium alloy steel(alloy studs) + surfacing

The Alloy studs inlaid surfacing welding vertical grinding roller is designed according to the working conditions and the wear resistance curve of the product. In the wear area, the powder metallurgy technology and surfacing technology are combined, and the special welding materials are used to form the inlay welding structure and metallurgical combination, improve the wear resistance and service life of the product, and achieve the regenerative repair to improve the service life of the product.

Ceramic alloy composite

The ceramic alloy composite grinding roller combines the characteristics of ceramic and alloy. It has both the wear resistance of ceramic and the mechanical properties of alloy, and is not easy to break or fall off. Due to the different properties of ceramic and alloy, the height difference of the surface is caused, thus forming a honeycomb structure, which increases the friction force and effective contact area of the surface, and helps to improve the grinding or crushing efficiency.

Production process: Alloy stud surfacing

Applicable machines: Roller press

Material types: Alloy steel (high manganese steel) + titanium carbide(stu) + surfacing;35CrMo or 42CrMo+surfacing

Applicable industries:Cement, chemicals, electricity, metallurgy, building materials, refractory materials

Adaptable materials: Limestone, slag, coke, coal and other materials

The roller material is mainly composed of Cr, Mo, V, W, Nb and other elements. The wear-resistant layer is placed on the outermost layer of the roller sleeve by centrifugal casting. The surface pattern is formed by casting.

Stud roller is composed of forged roller shaft, special alloy compound roller sleeve and wear-resistant cemented carbide studs.

The extrusion roller of alloy stud surfacing roller press has the following characteristics:

1. The base metal is high-strength and high-toughness alloy cast steel, which can be welded;

2. The corresponding alloy studs can be selected according to the working conditions. The wear resistance of the alloy studs is good, comparable to that of ceramets, and can be welded;

3. In case of peeling of alloy studs under abnormal conditions, the studs can be replanted by overlaying, which is convenient and fast;

4. The alloy stud forms a binding effect in the inlay welding structure, further improving the resistance of the alloy stud and the surfacing layer Abrasion and reliability;

5. The surface of grinding roller has good peeling resistance and integrity; The integrity of the roll surface can be guaranteed when foreign matters enter, Quickly restore size.