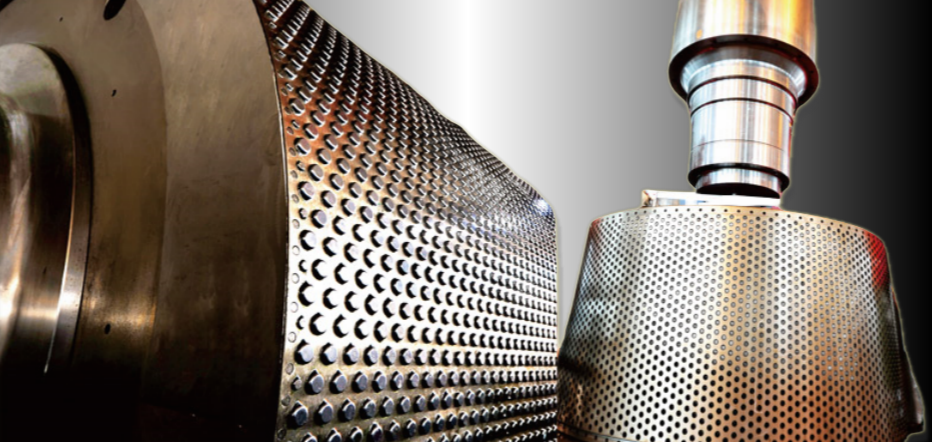

Extrusion roller of roller press

OEM tailor design

Product name: Extrusion roller of roller press/Roller Sleeve with Shaft/Hardfacing Roller

Production process: Alloy stud surfacing

Applicable machines: Roller press

Material types: Alloy steel (high manganese steel) + titanium carbide alloy rod + surfacing;35CrMo or 42CrMo+surfacing

Applicable industries:Cement, chemicals, electricity, metallurgy, building materials, refractory materials

Adaptable materials: Limestone, slag, coke, coal and other materials

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us’╝łzhiliwearparts@lyzhili.com’╝ē, because we are a customized factory for roller press spare parts.

The roller material is mainly composed of Cr, Mo, V, W, Nb and other elements. The wear-resistant layer is placed on the outermost layer of the roller sleeve by centrifugal casting. The surface pattern is formed by casting.

Stud roller is composed of forged roller shaft, special alloy compound roller sleeve and wear-resistant cemented carbide studs.The extrusion roller of alloy stud surfacing roller press has the following characteristics:

1. The base metal is high-strength and high-toughness alloy cast steel, which can be welded;

2. The corresponding alloy studs can be selected according to the working conditions. The wear resistance of the alloy studs is good, comparable to that of ceramets, and can be welded;

3. In case of peeling of alloy studs under abnormal conditions, the studs can be replanted by overlaying, which is convenient and fast;

4. The alloy stud forms a binding effect in the inlay welding structure, further improving the resistance of the alloy stud and the surfacing layer Abrasion and reliability;

5. The surface of grinding roller has good peeling resistance and integrity; The integrity of the roll surface can be guaranteed when foreign matters enter, Quickly restore size.

Stud roller is the latest developed new roller surface, which is composed of forged roller shaft, special alloy compound roller sleeve and wear-resistant cemented carbide studs. Every process, from raw material procurement to finished product delivery, is subject to strict quality control and equipped with advanced testing instruments and equipment to test the products.

Widely used in cement, metallurgy, mining and other industries.

Features are as follows’╝Ü

1. Easy maintenance and low maintenance cost;

2. Good adaptability to various materials and stable performance;

3. Long service life, increased production and efficiency;

4. Greatly improved overall wear resistance, strong material capacity and good wear resistance.

Our roller is a split roller sleeve. The roller shaft and roller sleeve are forged and processed separately before assembly. The base of the welding roller is made of forged low-alloy steel with high strength and good toughness. The rotary heating process is used to weld the "transition layer" on the surface of the base, and the "working layer" is welded on the surface of the "transition layer".

It is widely used in cement grinding rollers, metallurgy, steel, petrochemical and other industries.

Features:

1. Low cost and easy installation;

2. Advanced technology is used to replace traditional rollers;

3. The forging ratio is large, and repeated welding can be performed. The roller surface has a long service life and is not easy to peel off;

4. The combination of the welding layer and the base metal is a metallurgical combination with high bonding strength and good impact resistance;

5. Save energy and reduce pollution.