Function and selection of vertical mill dam ring

- 2025-03-07

- view countÿ¥

The dam ring in the vertical mill (vertical roller mill) is one of the key components that affect the operating efficiency and stability of the mill. Its role and selection need to be comprehensively considered in combination with material characteristics, process requirements and equipment structure. The following is a detailed analysis:

ð¡ÐThe role of the dam ring

1. Control the thickness of the material layer

The dam ring forms a stable material layer thickness by limiting the flow range of the material on the grinding disc. Appropriate material layer thickness can improve grinding efficiency, reduce direct wear between the roller sleeve and the grinding disc, and reduce vibration risks.

2. Extend material residence time

The height of the dam ring directly affects the residence time of the material in the grinding area. A higher dam ring can extend the number of times the material is crushed and improve the fineness of the powder; but too high will cause material accumulation and increase energy consumption.

3. Optimize air flow distribution

The gap between the dam ring and the edge of the grinding disc affects the contact efficiency between the hot air and the material. Reasonable design can improve the drying effect and prevent fine powder from being blown out prematurely.

4. Protect the equipment structure

Reduce the impact of large particles on the internal components of the mill, reduce the wear of the edge of the grinding disc and the nozzle ring, and extend the life of the equipment.

ð¤ÐSelection basis of dam ring

1. Material selection

High chromium cast iron: strong wear resistance, suitable for high hardness materials (such as slag, cement clinker).

Alloy steel (such as NM500): good comprehensive performance, strong impact resistance, suitable for medium wear conditions.

Ceramic composite materials: used for highly corrosive materials (such as desulfurized gypsum), but the cost is relatively high.

Overlay repair type: highly economical, and the service life can be extended by surface overlay.

2. Structural parameters

Height: adjusted according to material fluidity and target fineness. For example:

When grinding cement raw materials, the height of the dam ring is usually 80-120mm;

When processing high hardness materials such as slag, it can be reduced to 50-80mm to reduce over-grinding.

Shape:

Right-angle dam ring: suitable for materials with poor fluidity;

Arc-shaped or inclined dam ring: promote uniform distribution of materials and reduce local wear.

3. Process adaptability

Material characteristics:

Viscous materials (such as clay) require a lower dam ring to prevent clogging;

Materials with good fluidity (such as limestone) can increase the height appropriately.

System air volume: High air volume conditions require lower dam ring height to avoid excessive airflow resistance.

Capacity requirements: Large-capacity mills may require a segmented dam ring design to balance grinding and ventilation requirements.

4. Installation method

Fixed: simple structure, low maintenance cost, but adjustment requires shutdown;

Adjustable: height can be adjusted online through hydraulic or mechanical devices, with high flexibility and suitable for multi-variety production.

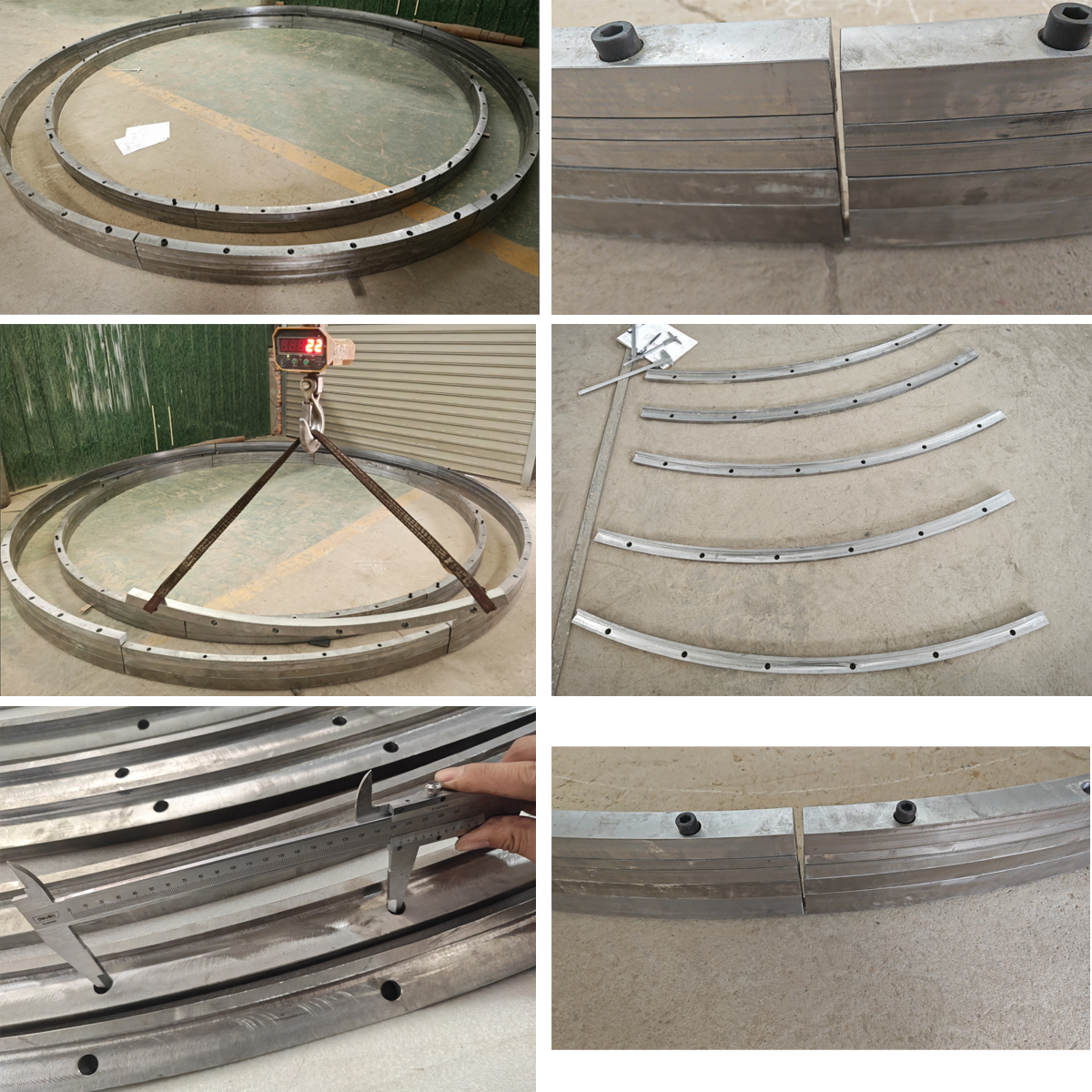

Our company produces vertical dam ring

ð¡ÐCommon types and applicable scenarios

1. Standard high-chromium cast iron dam ring

Applicable scenarios: ordinary cement raw materials, coal powder and other medium-wear materials.

Features: high cost-effectiveness, life of about 6-12 months.

2. Segmented wear-resistant alloy dam ring

Applicable scenarios: high wear and high impact conditions such as slag and steel slag.

Features: modular design, local damage can be replaced separately.

3. Ceramic composite dam ring

Applicable scenarios: highly corrosive chemical raw materials or high-temperature materials.

Features: Excellent corrosion resistance, but avoid severe impact.

ÍÐSummary

The optimization of the dam ring needs to be combined with the mill model (such as Loesche, Atox, MLS, etc.), material characteristics and production goals. For example:

Cement raw material mill: high chromium cast iron dam ring is preferred, with a height of about 100mm;

Slag micro powder mill: segmented alloy dam ring is recommended, with a height of 60mm and high air volume.

Through reasonable selection and adjustment, the grinding efficiency can be increased by 10%-20%, while reducing energy consumption per ton of product.