Why choose us?

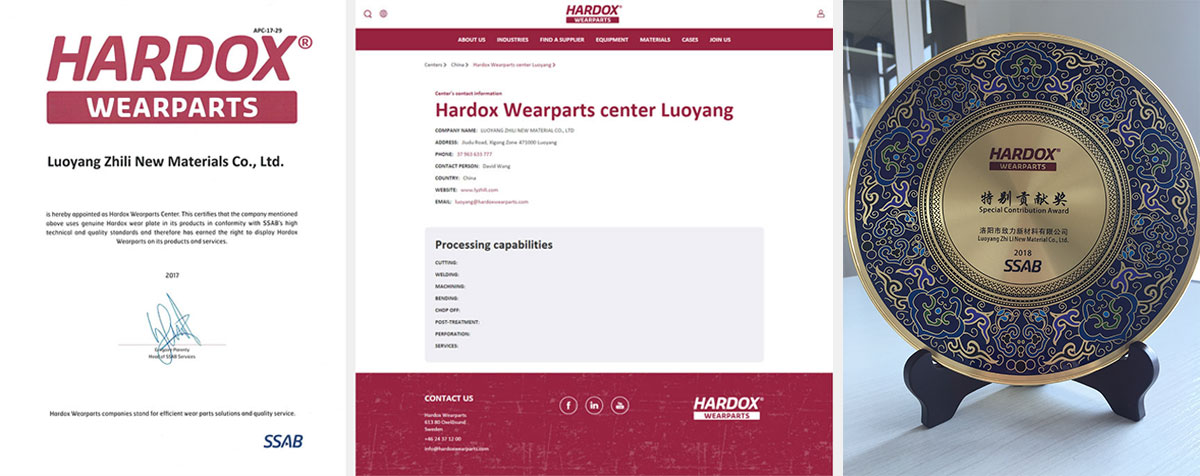

Official authored as Hardox wear parts

All of our hardox steel plate has its own qualification testing report and it is original from SSAB

SSAB focus on product quality of hardox. all of steel platefrom Hardox remark the product number in order to help buyer to track the manufacturer and product from SSAB.

What zhili do for you

We recommend the right steel plate to your based on our professional experience

We adopt WearCalcŌäó 2.1 official authorized by SSAB to ensure making tough decisions about choosing the right wear plate easy

WearCalc 2.1, SSABŌĆÖs proprietary wear prediction software, lets you quickly and easily calculate the relative service life for all Hardox steel grades, so you can optimize materials with regard to cost, wear, performance and weight.

With WearCalc 2.1, calculating component wear and optimizing your choice of wear plate just got easier

The impact wear model analyzes severe damage involving crater formation and extruded lips during impact, and model damage resulting in plastic deformation of the surface.

The erosion model predicts whether makeup of the abrasive materials will cause edges to penetrate the steel surface or to break. At the micro level, this model uses mineral hardness to calculate erosion on different types of wear plate.

The sliding wear model is based on two limiting curves representing the types of surface damage, plastic or cutting. The relationship between the hardness of the steel and the hardness of the abrasive material determines the damage mechanism and thus the relative service life.

Offering the cutting size of wear plate in customer needs

As official authorized wear parts centre, Our technology and hardware facilities have passed the strict requirements by hardox. Meanwhile, Hardox provides us with comprehensive technical support.

What kind of hardox product are available

There are eleven hardox wear plate in market, choosing the right one for you

Hardox wear plate-----working in the most challenging environment, tough and strength brand plate

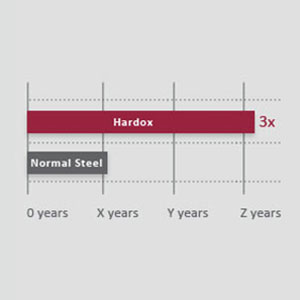

With its incomparable hardness and toughness, Hardox ® wear-resistant plate for wear-resistant steel (AR) established the standard of the world. Because of its unique quality, it can even play the role of bearing parts in many applications. It opening up new opportunities for structural design innovation.

Hardox steel is ideal for abrasive applications and hard wear conditions. No matter what wear challenges you face, Hardox hardtop wear-resistant panels provide better wear resistance, higher payload and longer service life for you. The Hardox range of products is characterized by the original wear-resistant plate are thinner and thicker than ever before. The dimensions range from 0.7-160 mm (0.027 6.25ŌĆ│), Pipe and round steel are also available.

With superior quality, reliability and performance, Hardox steel ensures that your equipment and business can operate normally.

Thanks to its high toughness, good bendability and weldability, this steel can be used in structures with moderate wear.

The products can be used in many different components and structures that are subject to wear. Hardox 450, with an extra 50 Brinell hardness over our 400 grade, provides better dent and abrasion resistance as well as longer wear life, so you can achieve even greater savings.

Hardox 500 increases payload and increases service life while maintaining good processability and toughness.

Hardox 500 Tuf combines the best properties from Hardox450 and Hardox500. The result is a wear plate with no real competition on the market.

Especially suited for extreme wear conditions, it can still be cut and welded, making it an excellent choice for high-performance applications.

Hardox® Extreme is an abrasion resistant steel with a nominal hardness of 60 HRC, intended for applications with extreme high demands on abrasion resistance. Typical applications is liner plates, etc.

Hardox® round bars come in diameters between 40 and 100 mm and lengths up to 5000 mm, and feature the same guaranteed properties as the wear plate. Delivered quenched and tempered to high tensile strength and hardness levels, Hardox® round bars represent entirely new possibilities for stronger and lighter product design. They also help optimize workshop procedures such as machining, welding and polishing.

Whereas traditional quenched and tempered wear-resistant steels lose hardness at higher temperatures, Hardox® HiTemp high-temperature steel delivers extreme wear resistance. Its properties are achieved by using high-quality raw material combined with a carefully controlled manufacturing process.

Hardox┬« HiTemp is delivered as 5ŌĆō51 mm (0.197ŌĆÖŌĆÖŌĆō2ŌĆÖŌĆÖ) plate. It can be cut, welded and machined using the same kind of machinery and technology as for conventional steel.