One-stop anti-resistant welding expert--Zhili New Materials

Started in 1992, the domestic famous wear-resistant parts and wear-resistant service one-stop supplier.Dedicated to mining, cement, power, steel, coal and other industries to provide wear-resistant equipment accessories services.

In order to give full play to the role of surfacing layer, high quality surfacing material and high efficiency and reliable surfacing technology are essential

Why choose us-----advance welding and welding material

As a professional one-stop wear abrasion supplier, we are not only solve your problem of surfacing, but also consider the cost and operability of the enterprise.

World advanced welding provider

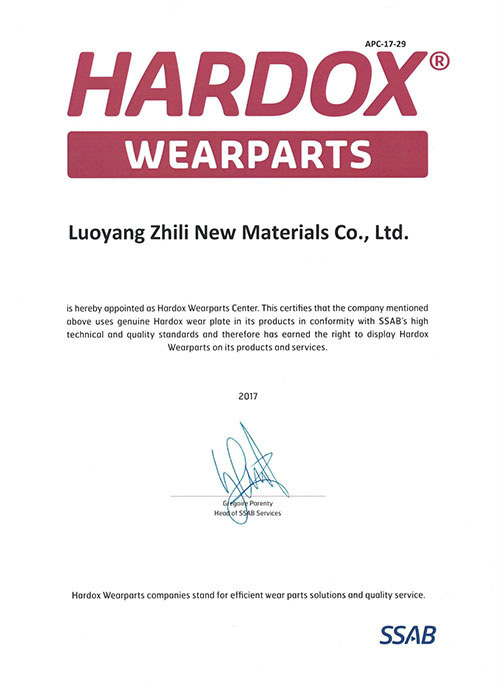

We are authoried as hardox wear center by SSAB Swedish Steel Group and has its global leading Duroxite ® wear-resistant overlaying welding technology

Ō£ö All products adopt ASTM G65 standard of American national laboratory

Ō£ö Database case support for all SSAB processing service centers around the world

Ō£ö SSAB has over 100 years of metallurgical technology experience

Therefore, we have the ability to bring you the world's best surfacing wearable solution

Cost-effective solution provider

As a professional one-stop supplier of surfacing and abrasion resistance, we should not only solve your problem of surfacing, but also consider the cost and operability of the enterprise.As a professional one-stop wear abrasion supplier , we not only have to solve your surfacing problems, but also consider the cost and operability of the company.In order to help customer save the production cost, we have established a cooperative relationship with many domestic welding material manufacturers and selected high-quality material suppliers based on Duroxite® advanced technology.

Why choose us --------- Reliable and mature construction team

As the professional one-stop hard facing processing supplier , we pay more attention to reduce customer cost rather than solve the surfacing welding problem.

World famous technical group with strong welding background

In order to bring more reliable, stable and efficient service guarantee to the enterprise. The team of engineers has passed the advanced training certificate of welding enterprises. Adopting strict management standard and comprehensive service tracking mechanism

Per construction, we will customize an integrate service plan based on the accrual working condition you given. if you can't provide these information, we will arrange the technical team come to your side and collect the detail information we need.

In the construction process, we will arrange the experienced welding engineers to provide you with reliable online or offline hard facing service guarantee.

At the end of the construction, we need know your wear condition regularly and provide the foundation for the next round of surfacing quality.

Why choose us---- Advanced welding equipment and inspection system

Features of fixed welding equipment

It apply to grinding mill, coal grinding, slag grinding and roller press under off-line welding. The working performance of repaired items is equal to or even better than the new product

Advantage of fixed welding: The base plate is high-chromium cast-iron which are better control its surfacing temperature. Making welding surface more accuracy.

ŌŚÅ Individual durable heavy duty structure

ŌŚÅ Motors with encoder for closed-loop control to ensure accuracy

ŌŚÅ Linkage between axis

ŌŚÅ Durable welding torch, combined with 4-weel wire feeding system

ŌŚÅ Modular digital control

ŌŚÅ Characterized welding process: suitable for open/submerged arc welding and gouging welding

ŌŚÅ Suitable for welding wires of diameter 1.2mm to 3.2mm

Features of fixed welding equipment

Customizing online welding service accord to customerŌĆÖs site working condition in order to Improve toughness of the product , reduce energy consumption, and track usage.

Advantage of portable welding:

ŌŚÅ Special light-weight aluminum alloy structure for Unique ŌĆ£install per useŌĆØ equipment, easy to assemble, install and transport.

ŌŚÅ suitable for most of the working conditions

ŌŚÅ Simple assembly process for welding torch, combined with 4-weel wire feeding system

ŌŚÅ Modular digital control

ŌŚÅ Characterized welding process: suitable for open/submerged arc welding and gouging welding

ŌŚÅ Suitable for welding wires of diameter 1.2mm to 3.2mm

Comprehensive quality monitoring system

Quality is the fundamental value of corporation. We have a full advanced and efficient checking system for materials and products

ŌŚÅ Spectrometer

ŌŚÅ Tensile testing machine

ŌŚÅ Metallographic analysis system

ŌŚÅ Bench hardness tester

ŌŚÅ Wear testing machine

Particle size analyzer plus other advanced testing equipment, established innovative laboratory to unsure the quality requirement of materials and products.

Anti-abrasion welding product we provide

Duroxite® overlay plate series

From wearpart's Duroxite ® series composite board products will bring you more lasting use cycle, it can add weeks, months, even years of trouble-free operation to your most extreme wear situations.

It is formed by depositing wear-resistant materials on the top of low carbon steel or Hardox tough wear-resistant steel substrate to form an extremely wear-resistant composite material. The best composition of carbide ensures that the base metal and welding layer uniform adhesive, thus make Duroxite ® has a very high abrasion resistance and long service life

Duroxite ® made by SSAB Sweden steel group, SSAB has widely metallurgy knowledge and technology in the field of wear resistance.

The Duroxite product range is targeted at different types of wear, such as abrasion, impact, heat, metal-to-metal and erosion wear. DuroxiteŌäó is particularly well suited to fighting sliding wear from exceptionally hard particles such as minerals containing quartz.

China Premium anti-resistant series

Flux-cored wire

we provide proper wear resistant flux cored wire for various industrial applications and abrasion.

ŌŚÅ Key Benefits

We have the wire formula by independent research and development and advanced overlaying arc welding. The advantages are high deposition rate, no spatter during the process, easy to forming and getting high weld quality. The fixed cost will be reduced 30-40%, the lifetime is 2-3 times as new component. It is success widely used in electric power,cement,mining,petroleum,chemical industry,rail way, valve, ship and sugaring filed.

ŌŚÅ Apply field

It widely apply to power, cement, steel, mining, petroleum, chemical industry, railway, valve, sugar, shipbuilding and other industries

We can provide proper flux-cored for different application at industrial field. No matter in the factory or at site, new component part, we all have proper process and way to welding and fix.